Lean Green and Sustainability in VET

In recent decades, Sustainability has been a constant concern and a priority for the industrial sector, due to the negative impacts that emissions and different types of waste represents for the environment and its preservation.

Although the industry has a considerable contribution to the evolution of this problem, this sector is essential for the production of products and goods, as well as for the promotion of employment and for the economic development.

As such, in addition to applying demanding environmental regulations, it is crucial that the industry think of ways to reduce the impacts that these emissions and wastes represent for environmental development.

Thus, there is a combination between the LEAN concept, which corresponds to the implementation of management tools and continuous improvement, and the GREEN concept, which is associated with sustainable practices and processes incorporated in environmental management systems (Vasconcelos et.al., 2013).

Indeed, Lean Green emerges as a methodology consisting of methods and techniques that aim to optimize and improve production processes, incorporating ecological practices that reduce industrial waste and emissions, with the objective of minimizing the risk and impact on the environment, without hamper delivery time and product quality (Diniz, 2018). To this end, the involvement and responsibility of leaders and employees is essential for the application of this process and obtaining the desired results, as well as it is necessary to prepare future industry employees in order to raise awareness of this cause.

In this way, as seen in the study by Medeiros (2019), “The perspectives of trainees who attend Vocational Education: a study in a vocational school”, Vocational Education represents a good option for many young people and adults who want to learn a profession and at the same time, obtain a double certification, in order to enter the labor market more quickly.

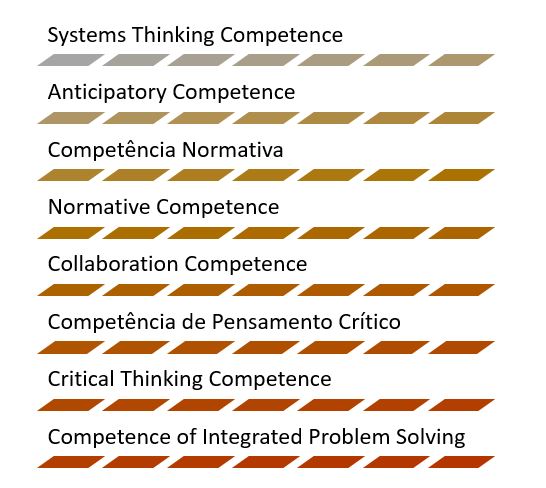

In addition to the essential and technical skills, which are understood as knowledge, skills and attitudes, that trainees will acquire along their training path, it is essential that this teaching path promotes the development of a set of transversal key skills for Sustainability, presented in Figure 1, so that they can adopt a sustainable lifestyle, and therefore contribute to the construction of a sustainable corporate environment, at a professional level.

Source: Unesco, 2017, adaptado de De Haan, 2010;

Rieckmann, 2012; Wiek; Withycombe; Redman, 2011

Thus, among the various existing actions to reduce waste and emissions, the “5S” method stands out for this purpose, which is part of the set of Lean philosophy tools, practiced at ATEC – Training Academy, which qualifies for the market, namely for the industry in general.

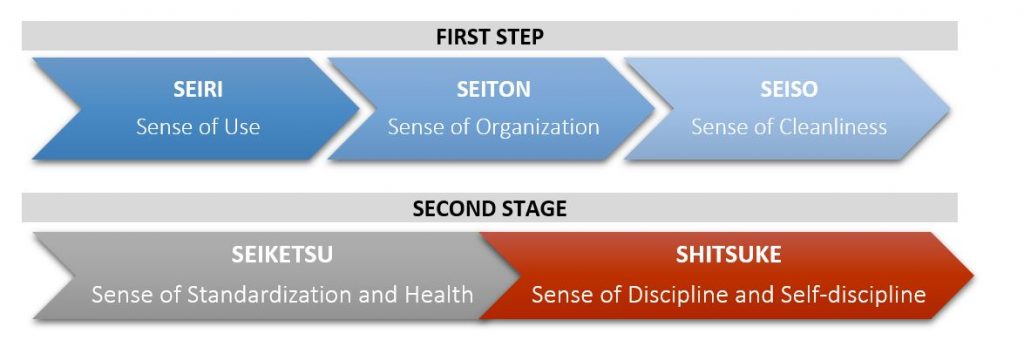

The 5S method was developed in Japan and is based on five words known as oriental cultural senses.

Its main objective is to create the workplace in a clean, organized and accessible space, by reducing waste and wasted resources and space, in order to increase operational efficiency and, consequently, productivity. Figure 2 shows the phases for implementing this method, which must be evaluated using performance indicators to measure the evolution of the continuous improvement process.

Figure 3 shows the before and after, respectively, of a training workshop in the field of automotive mechatronics at ATEC where the 5S method was implemented. In the example, unneeded material was removed and access was granted to what is really used during training activities as well as to safety equipment.

Visual Management also integrates the Lean concept and enables an effective support for the 5S method, as it is applied to transmit information, define and signal, through labels, lines and color codes, storage and storage places for materials, equipment or waste, as illustrated in figure 3 and 4.

Bibliography

Simas, A. (2016). Gestão Visual em Sistemas Lean: Metodologia de Uniformização. Dissertação de mestrado. Universidade Nova de Lisboa. Available from https://run.unl.pt/handle/10362/20081

Diniz, L. M. (2018). A Sinergia entre a Sustentabilidade e a Produção Eficiente pela Aplicação do Lean-Green. (Dissertação de mestrado, Universidade da Beira Interior, Covilhã, Portugal). Disponível a partir de https://ubibliorum.ubi.pt/bitstream/10400.6/9688/1/6531_13886.pdf

Educação para os Objetivos de Desenvolvimento Sustentável: objetivos de aprendizagem (2017). ISBN: 978-85-7652-218-8. Available from https://unesdoc.unesco.org/ark:/48223/pf0000252197

Medeiros, A. P. (2019). As perspetivas dos formandos que frequentam o Ensino Profissional: um estudo numa escola profissional (Dissertação de mestrado, Universidade Aberta, Lisboa, Portugal). Available from https://repositorioaberto.uab.pt/bitstream/10400.2/9095/1/TMAGE_AnaPaulaMedeiros.pdf

Reis, M., Soares, R., Santos, M. & Walker, A. (2018). Implementação do Programa 5S: um estudo de caso em uma empresa de construção civil. Available from https://www.researchgate.net/profile/Marcos_Dos_Santos6/publication/325378169_Implemenacao_do_Programa_5S_um_estudo_de_caso_em_uma_empresa_de_construcao_civil/links/5b08c0d7aca2725783e5e957/Implemenacao-do-Programa-5S-um-estudo-de-caso-em-uma-empresa-de-construcao-civil.pdf

Site da Sociedade de Toxicologia Ambiental e Química (SETAC). Available from https://www.setac.org/

Vasconcelos, D., Neto, J. & Viana, F. (2013). LEAN e GREEN: A CONTRIBUIÇÃO DA PRODUÇÃO ENXUTA E DA GESTÃO AMBIENTAL PARA A REDUÇÃO DE DESPERDÍCIOS. Rio de Janeiro / RJ. Available from http://www.anpad.org.br/diversos/down_zips/68/2013_EnANPAD_GOL206.pdf

Ana Paula Medeiros

Development and Pedagogical Coordination

ATEC – Academia de Formação ana.medeiros@atec.pt